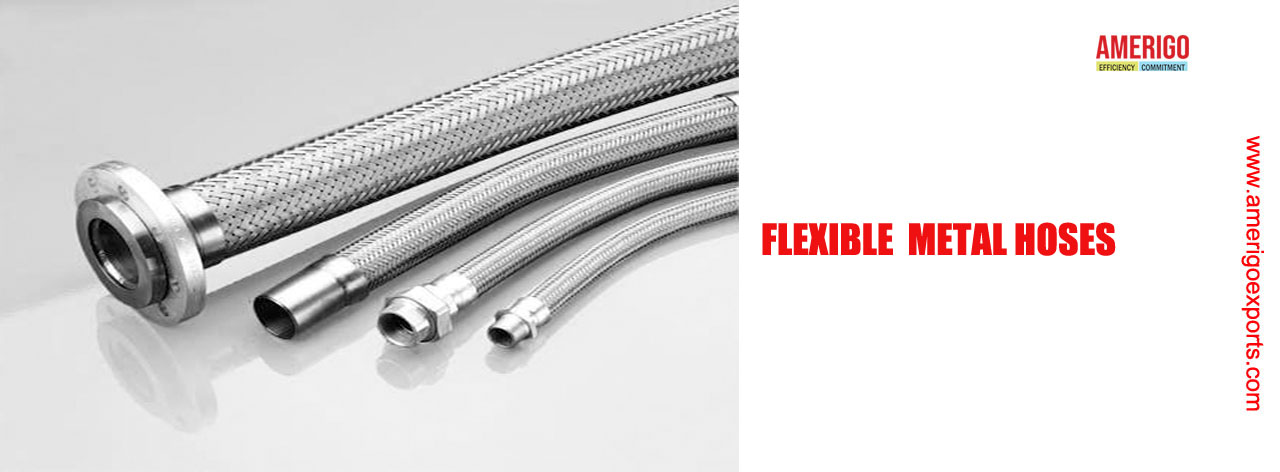

We AMERIGO, are leading manufacturers and exporters of high quality Flexible Metal Hoses in India. The metal hoses are used in steam lines, compressed air and gas distribution systems. Handles corrosive fluids and gases safely. Transfers petroleum products and fuels in refineries and offshore platforms.

HVAC & Plumbing : Heating Systems: Connects boilers, radiators, and heat exchangers. Air Conditioning: Used for refrigerant and ventilation ducts. Water Supply: Flexible connectors in plumbing systems reduce vibration and movement.

Automotive & Aerospace : Exhaust Systems: Absorbs vibrations and compensates for thermal expansion. Brake & Fuel Lines: High-pressure hoses in braking and fuel delivery systems. Aircraft Applications: Used in hydraulic and pneumatic systems.

Power Plants & Energy : Turbine Connections: Transfers steam and cooling fluids in power plants. Solar & Nuclear Plants: Carries high-temperature fluids safely.

Food & Pharmaceutical Industry : Sanitary Fluid Transfer: Used for sterile transportation of liquids in food processing and medical applications. Cryogenic Applications: Handles liquid nitrogen and oxygen in pharmaceutical industries.

Marine & Shipbuilding : Fuel & Water Transfer: Used in ships for fuel, ballast, and water systems. Exhaust & Cooling Systems: Helps dissipate heat from engines.

Robotics & Automation : Cable & Hose Protection: Protects wiring and fluid lines in automated machinery. Motion Compensation: Absorbs movement and vibration in robotic arms.

Technical Specs : Flexible metal hoses are used in various industrial applications for conveying fluids and gases under pressure. Their technical parameters depend on material composition, design, and intended application. Below are the key technical parameters:1. Nominal Diameter (DN) : Ranges: Typically from 6 mm to 300 mm (¼" to 12"). Determines the flow capacity.

2. Hose Material : Common materials: Stainless steel (SS304, SS316, SS321), Inconel, Monel, and other corrosion-resistant alloys. Selection depends on temperature, pressure, and chemical compatibility.

3. Braid Material : Usually stainless steel (SS304, SS316) for reinforcement. Provides mechanical strength and enhances pressure resistance.

4. Pressure Rating : Varies based on diameter, material, and construction. Typically ranges from 10 bar to 300 bar (higher for specialized designs). Considerations include working pressure and burst pressure.

5. Temperature Range : Stainless steel hoses: -200°C to +600°C (depends on material). With PTFE lining: -70°C to +260°C. Affects hose flexibility and service life.

6. Bending Radius : Defines the minimum radius the hose can be bent without damage. Typically between 1 to 12 times the hose diameter, depending on construction.

7. Hose Construction : Corrugation Profile: Annular or helical. Single or Multiple Braiding: Affects pressure capacity. Lining Options: PTFE, rubber, or other coatings for chemical resistance.

8. End Fittings : Common types: Flanges, threaded connections, camlock couplings, quick-release couplings, welded ends. Materials match hose specifications.

9. Applications : Steam, gas, and liquid transfer in industrial piping. Vibration absorption in mechanical systems. High-temperature and high-pressure environments.